Class

- D Audio Power Amplifiers:

|

C |

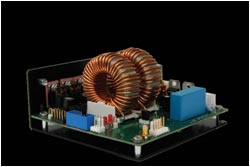

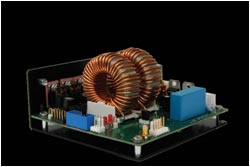

The

Class-D Audio Power Amplifiers used in all Charles Grecco

products are the culmination of over 12 years of development.

Features include: |

| * |

Compact

size: 4.25 x 4.1 x 1.75" (108 x 105 x 45mm) |

| * |

High

output power: >1000Wrms |

| * |

Wide

bandwidth: <5Hz to >35kHz |

| * |

Low

distortion: <0.02% at 10W output, <0.1% at rated

power |

| * |

High

efficiency: >90% |

| * |

On-board

microprocessor for amplifier control and status

monitoring and communications |

| * |

Full

protection against load faults and thermal stress |

| * |

Isolated

crystal-controlled clock for minimum noise |

| * |

Proprietary

feedback network that minimizes frequency response

errors related to variations in load impedance

These state-of-the-art amplifiers are powered by a companion

switchmode power supply, that also features high efficiency

and compact size. Its switching frequency is specifically optimized to

minimize noise artifacts in the audible range.

Each powered loudspeaker also features a DSP-based active crossover

driving its array of up to 4 amplifiers. This DSP provides

steep crossover slopes to minimize loudspeaker out-of-band response

anomalies and advanced pattern control. It also provides additional time-alignment and

fine equalization of all drivers in the array.

John Levreault

Orvelle Technologies, Inc.

Amplifier Design |

Woofers:

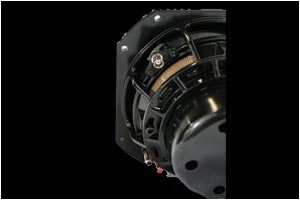

Vance Dickason called long time friends and woofer designers

Patrick Turnmire, and Enrique Stiles of Redrock Acoustics.

These two men are truly remarkable at what they do. When

you hear Dickason say that “they may be the world’s

best driver designers” you know you have something.

Working exclusively with the world’s largest driver

manufacturer, Sonavox, Turnmire developed the world’s

standard in driver modeling software, SpeaD. Turnmire

and Stiles developed for Charles Grecco what they believe

is the world’s most advanced line of raw drivers.

Ranging from 4 inch midrange drivers to 15 inch woofers

and sub-woofers, these products not only meet the stringent

requirements for use in the pro audio industry but they

have also helped develop and incorporated the most sophisticated

real-time sensing devices which will continually monitor

the temperature of the coil and its excursion in future

designs. The four-inch mid bass driver used in the line

array was tested with pink noise at 200 watts for 8 hours

of continuous use with a compression loss of only 2dB.

This is a result of the cooling provided by their mMag

technology is licensed exclusively in pro audio by Charles

Grecco.

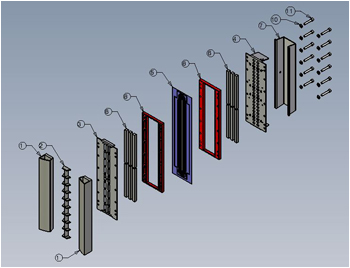

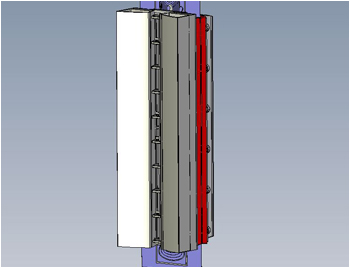

Ribbon Tweeter:

The use of planar magnetic drivers for pro sound provides a

remarkable clarity and detail that is simply not possible with

compression drivers and horns. The large radiating surface

area and extremely low moving mass of the tensioned film diaphragm

provides unparalleled speed and openness.

Planar magnetic drivers; sometimes referred to as ribbon speakers,

have long been regarded as the best high frequency devices

available. Additionally, they have also had a reputation for

being fragile and inefficient. Currently, with the availability

of neodymium iron boron magnetic material and significant advances

in the materials science related to the construction of etched

foil clad polymer film, today's planar magnetic drivers are

as efficient and handle several times the power of even the

best compression drivers with a fraction of the distortion.

The sensitivity of the 11.5" driver designed for Charles

Grecco is 105 dB@1w/1m, and is capable of handling 3600 watt

peaks for 200 ms. The output is fed into a manifold wave guide

to create a radiating source width of 0.75", resulting

in a remarkably wide, (110 degree) and even horizontal radiating

pattern. High frequency extension is well beyond 20kHz.

The subjective experience when listening to these systems is

that of hearing the best audio reproduction available anywhere,

including the highest priced, most sophisticated consumer loudspeaker

systems. That fact that this design when used in tandem in

the Charles Grecco line array can effortlessly attain the SPL

levels required for live sound in even the largest venues is

a monumental technical achievement.

David Graebener

Ribbon Designer

top

BMS

4595 COAX Compression driver:

FEATURES :

| • |

Extended Bandwidth

(300 - 22000 Hz) |

| • |

Neodymium Magnet

Assembly |

| • |

With two Subsystems

in one, each Driver covers a smaller Frequency range

for increased Power Handling, high Dynamic and extremely

low Distortion |

| • |

Excellent Phase Coherence |

| • |

Perfect Time Alignment

without Problems of Multi-Source Interference |

| • |

Ultra light Weight

and small Size |

The 4595ND is a 1,5" coaxial compression

driver delivering a real coherent single point wave front

without hot spots with excellent phase coherence and perfect

time alignment. The driver is in fact a 2-way system employing

two concentric annular ring diaphragms. Each driver covers

a smaller frequency range for increased power handling, high

dynamic and extremely low distortion.

The larger of the two reproduces middle frequency

from 300 Hz upward, crossing over 6,3 kHz to the HF transducer

which is capable of reaching 22 kHz. The large diaphragm excursion

of max. + / - 0,8 mm results in high output and increased power

handling up to 1300 W peak. The voice coils may be driven in

conjunction with a passive crossover or driven individually

from an active crossover. The outer casting features extensive

heatsinking ensuring high power handling and low compression.

top

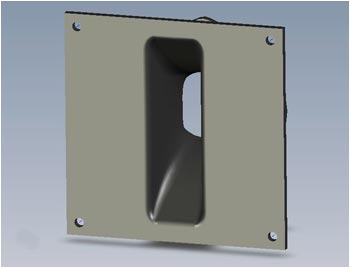

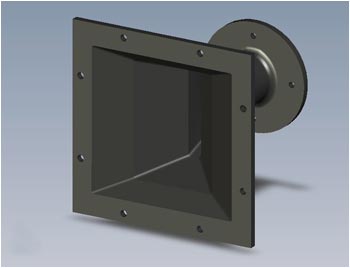

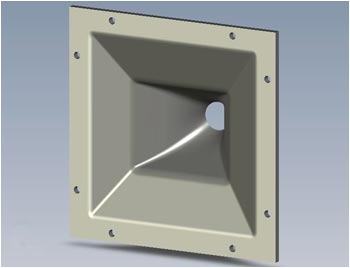

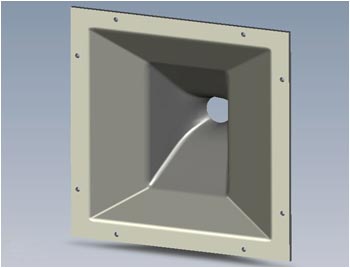

Horns:

Constant Directivity Horns

All of the horns

in our product line have been exclusively design by Mr. Charlie

Hughes. You will find several articles in Live Sound Magazine,

as well as Syn-Aud-Con white papers. He is also a member

of the EASE and EASERA Developers Group.

The main design criteria

we set out when developing this line of horns was precise

pattern control, as well as exceptional sound quality. Mr.

Hughes has not disappointed. These horns are the most accurate

and musical horns I have ever offered.

There are four standard

horn patterns for the Installation Series and the Wedge Trap

Series. They are: 60X45, 60X60, 90X45, and 90X60. The front

fills have a 120 degree Slot horn, (pictured) as well as

45X90 and 45X60. As needed, we can add specific horn patterns

to suit your customers’ needs.

top

Cabinet Designs and Testing:

The boxes are manufactured in Nashville TN, using the latest in

automated machinery. We use 13 ply Baltic Birch. Once coated with

truck bed liner, the cabinets are sent to another facility in

Nashville for component loading and final assembly. All products

are acoustically tested before leaving the facility. All EASE

data is independently provided by NWAA labs (http://nwaalabs.ipower.com/).

top

|